Exegy plastic heat exchangers come in two versions:

These heat exchangers can heat and cool air, pre-condition fresh air, and recover residual heat from gases and liquids.

Exegy heat exchangers have many advantages over conventional heat exchangers. For example they are:

The AeroX and HydroX heat exchangers are ideally suited for industrial, agricultural and offshore applications. Heating, cooling and heat recovery are just some of the possibilities offered by these heat exchangers which are often combined with air scrubbers, TES systems, heat pumps, etc.

These heat exchangers consist of purpose-developed flexible thin-walled polyethylene (PE) tubes, which ensure maximum heat transfer. The materials chosen ensure that the heat exchanger packages can withstand temperatures far below freezing point. The liquid in the heat exchanger may freeze, but this will not damage the packages. Since the heat exchanger is made entirely of PE, it is resistant to a wide range of liquids and aggressive environments. This has made corrosion a thing of the past. Since dirt does not easily adhere to the smooth surface of the tubes, the units require little or no maintenance. And any cleaning needed can be done very easily. Together with the AeroX's corrosion resistance, this is your guarantee of the continued high efficiency of the AeroX for many years. This is in stark contrast to conventional heat exchangers. The tube packages can be interconnected to increase capacity. This enables optimum solutions for all situations to be created by these highly versatile heat exchangers

Before leaving our factory, our heat exchangers are extensively tested for any leaks and production errors.

Would you like to know more about what Exegy heat exchangers can do for you? Please contact us, free of any obligation!

In the case of the AeroX air-to-water heat exchanger, the liquid (usually water) flows through the plastic tubes of the heat exchanger. The gas (usually air) flows between the water-filled plastic tubes. The difference in temperature between the water and the surrounding air will cause energy (heat) to be transferred from the water to the air, or vice versa, from the air to the water.

In the case of the HydroX water-to-water heat exchanger, the liquid (usually water) flows through the plastic tubes of the heat exchanger and between the water-filled plastic tubes. The difference in temperature between the water in the tubes and the surrounding water causes energy (heat) to be exchanged.

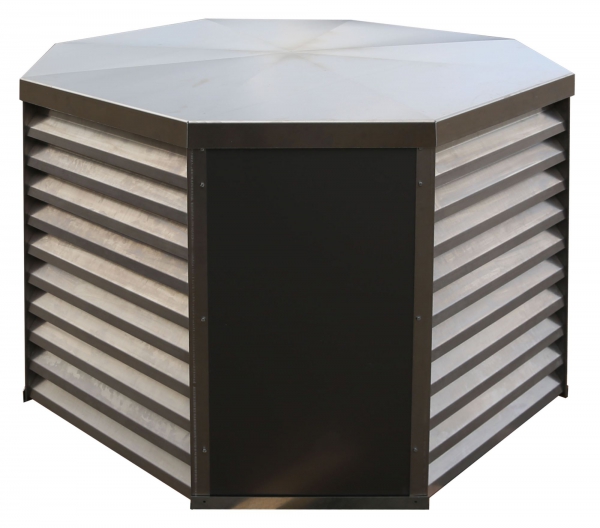

The Cube has been designed to enable two, three, or four sides to be fitted with heat exchanger packages. Each filled side contains five AeroX air-to-water heat exchanger packages. When fitted with a housing, the Cube can be used as a roof unit or installed along a building.

As standard, we use Danfoss frequency inverters to control the speeds of pumps and fans. Exegy supplies these frequency inverters from stock.

AeroX heat exchangers are extremely suitable for thermal energy storage (TES) systems and energy recovery from gas scrubbers.

Special control computers have been developed to achieve an optimum climate, energy efficiency, and thus cost efficiency.